Ten Plus Ways Underground Storage Tank Systems Leak That Aren’t So Obvious

If an underground storage tank (UST) system passes tightness testing and has an automatic electronic leak detection system, then the property is clean, right? Well, maybe not. Presented below are eleven not-so-obvious ways UST systems can fool you and lay claim your pocketbook. Extreme caution is advised evaluating UST systems.

In each of the following eleven circumstances, the UST system (including the product piping) would pass both precision tightness testing and electronic leak detection (tank gauging)…but the gasoline station would still be contaminated from petroleum release(s).

(1) Surface spills at the dispensers are a common source of petroleum contamination at gasoline stations and truck stops. Hundreds of gallons of petroleum are spilled at a typical dispenser annually, and much of this released petroleum makes its way into the soil and groundwater. Above, diesel dispenser spillage at a typical station.

(2) Modern UST systems include product fills with catch basins (above) such that when a petroleum delivery is made, any accidental spillage from the hose is captured. However, older UST system fills had no such catch basins. If an older UST system was retrofitted with a catch basin (like the one above), then any petroleum that was historically spilled remains on-site, underground, and within the gravel fill supporting the UST body. See the spilled fuel floating on the water? All the petroleum spilled before this retrofit was completed was released into the dirt or supporting gravel surrounding the UST fill and remains on-site underground. Not good.

(3) Modern UST systems have various features such as ball check valves, secure product fill connections, overfill catch basins, and alarms to prevent overfill events. However, on occasion, they still occur. Spilled product ends up on and in the ground and in the supporting tank gravel or fill as explained under (2) above. Shown above is a super unleaded gasoline delivery taking place with a Stage I Vapor Recovery hose in place.

(4) Few petroleum dispensers appear this clean inside. Newer dispenser pumps such as the one above include catch basins (green) that effectively contain any releases from the dispenser’s steel, fiberglass, or flexible coupling piping. However, older dispensers did not include any such catch basins, and releases (drip, drip, drip) freely leaked into the ground beneath the pump island. So bad is this problem that some states (such as Florida) require specific soil and groundwater testing beneath all former dispenser locations when a UST system is closed (permanently removed from service).

(5) Just as flexible couplings (braided wire or plastic piping) can come loose, fail, or otherwise leak beneath the dispensers, they can also fail within the UST manways. Free product and petroleum vapors in the manway can leak (a) into the subsurface through exposed soils peripheral to the manway lid, and (b) through faulty gaskets bolting the manway to the UST body (visible above as a bolted, large diameter washer that looks like a hoola-hoop). Moreover, UST tightness testing personnel can either (a) fail to properly secure flexible couplings after tightness testing, or (b) re-secure flexible couplings that have already caused a reportable release and erroneously report to you that the UST system is tight. As seen above, solvent-like chemicals (such as gasoline) dissolve sealants.

(6) Many modern UST systems are equipped with electronic leak detection and tank gauging systems that alert the operator to a loss of product (a release) or of a need for a product delivery. Automatic electronic leak detection such as the one above equipped with continuous statistical leak detection (CSLD) are able with computational analysis able to determine if there is a product loss based on total system throughput. However, without the CSLD option, such systems cannot detect losses greater than 0.1-gph. This means a loss of 876-gallons of petroleum per year…without an alarm to the operator.

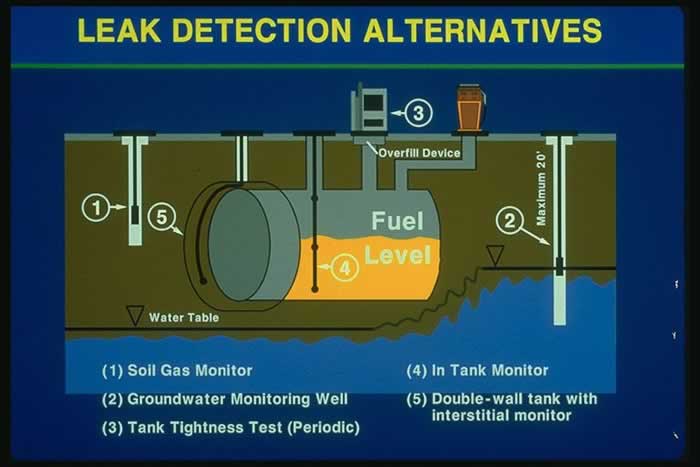

(7) Do an internet search for the words falsified, tank, and testing. The results are troubling. There is too much at risk owning and operating a petroleum UST system to rely solely on UST testing results developed by a relative stranger over an hour or so every several years. Federated Environmental recommends using various ongoing methods to ensure your UST system is tight. A UST testing report is only as reliable as the person delivering it to you. Various other methods are illustrated above…it’s like double-checking your homework.

(8) On occasion, gasoline station owners will experience a product lines failure and replace the product line…but “forget” to mention it to regulators, buyers, and inspectors. When the property is presented for sale, they are quick to present current passing tightness testing results and leak detection printouts. However, petroleum contamination remains on-site from the product line failure and release they failed to mention. But…equipped with knowledge….there are clues that a failed product line replacement has occurred. The first clue is concrete or asphalt cutout areas tracing the product lines from the USTs to the dispensers. The second clue is product lines willy-nilly laying about on-site or improperly discarded on-site (as above). Look for these tell-tale signs.

(9) Many older gasoline stations have UST fill ports or manways (as above) that are constructed such that storm water, and any petroleum spillage on the property, drains into them. Of course, when the manway itself drains and/or leaks over time, the spilled surface petroleum ends up in the soil and groundwater below. Observed, accumulated storm water within manways is a line item in every UST system inspector’s checklist.

(10) It is not uncommon to discover a contaminated gasoline station with a relatively new UST system. Careful examination of the UST system and testing reveals that the new UST system is leak free. Further investigation of the matter reveals that the UST installation company, in service of a major UST installation contract, neglected to (or chose not to) report the release during their new UST installation. This course of events is not as nearly as common as it used to be. Nevertheless, it is possible to have what we call a “new tanks in dirty dirt” condition. Of course, the leak detection system would erroneously report “all systems normal.”

(11) UST systems in the U.S. are pressurized; petroleum is pumped from within the UST through the product lines in the manway and ground to the dispensers. Modern pressurized systems include detection devices that actively monitor the product flow through this pathway. If there is a massive, immediate, discrepancy (loss of product is detected), an automatic electronic relay switch shuts down the internal UST pump.

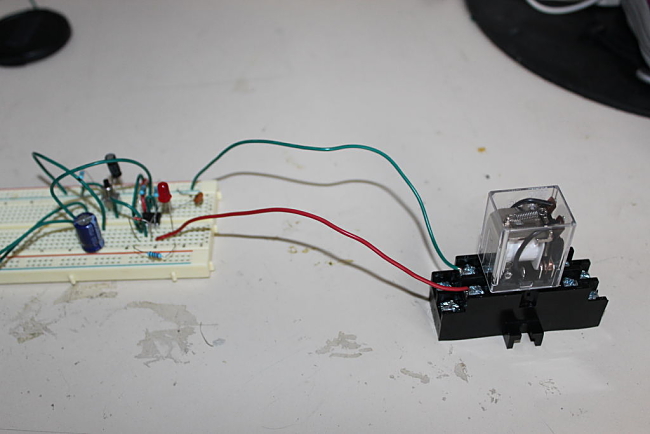

When an automatic electronic shutoff relay fails, the internal relay pump will continue to pump fuel…even if the dispenser nozzle is in its cradle on the side of the dispenser. If the pressure is sufficient, it can cause a fitting or flexible coupling within the product line to fail. The internal UST pump will continue to pump fuel until someone cuts off the power in the station’s circuit box. Although a rare occurrence, we’ve seen it happen. One 600-gallon loss of product in 10-minutes resulted in a $600,000.00 cleanup. Above, high voltage electric relay being bench tested.